Die casting is a manufacturing process that we use to help construct smooth, well-dimension metal products. The process consists of forcing molten metal into the mold at very high pressure into reusable metal dies.

The die casting process can be described as the shortest distance between the raw material and the finished product. It is completed in one of two ways: hot chamber die casting and cold chamber die casting. Let’s see how the two processes compare below.

What Is Cold Chamber Die Casting?

Based on the name alone, it’s easy to assume that cold chamber die-casting uses cold metal to create reusable metal dies. In fact, cold chamber die-casting refers to the process in which the molten metal is heated. Cold chamber die-casting heats the metal in a different furnace, which is then transferred into the casting machine. There is a pressurized plunger in the separate furnace that forces the molten metal into the mold, where it takes its final shape.

There are only certain types of metals that can go through cold chamber die-casting successfully, including aluminum, magnesium, and copper. These metals have a relatively higher melting point that requires them to reach their molten state before they are forced into the chamber.

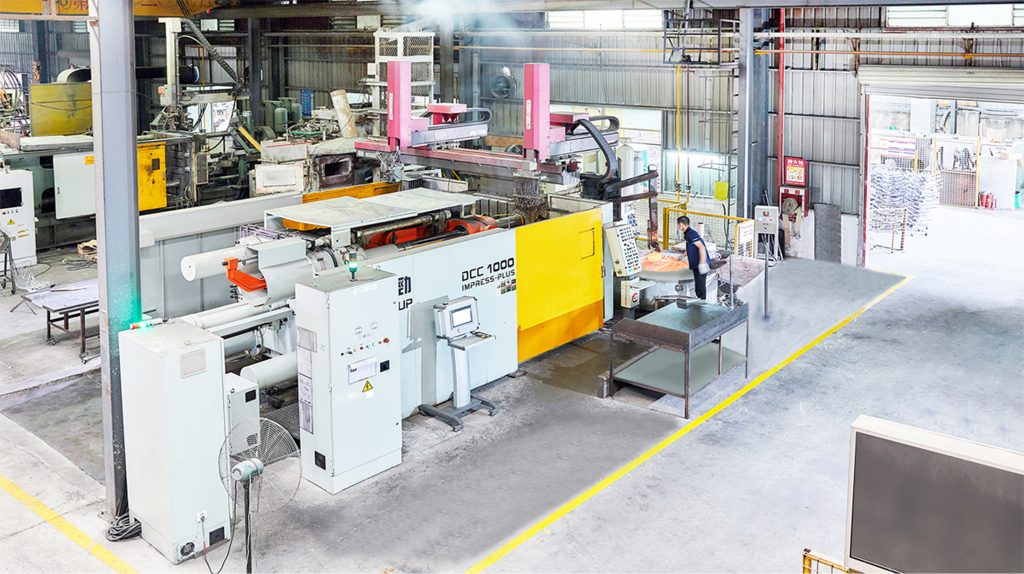

Die cast parts that are manufactured through the cold chamber process have advantages that can include: very detailed design, thinner part walls and enhanced mechanical properties. Wetron skilled team has over 15 years of experience in cold chamber die casting technology and manufacturing, we have different tons of cold chamber die casting machine in house at the moment.

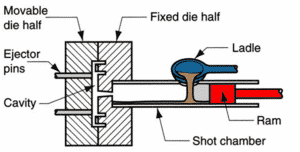

As comparison from hot chamber die casting, melted metal is ladled from the furnace into the shot chamber through a pouring hole. While the general function of the cold chamber machine is similar to hot chamber, cold chamber works with a horizontal orientation and does not have a gooseneck.

Instead, the plunger forces metal through the shot chamber into the die at pressures ranging from 2,000 and 20,000 psi. The plunger holds the pressure and retracts after solidification. The clamping unit and mounting of dies is set up the same as hot chamber, however, the cover die for a cold chamber machine does not have a gooseneck or nozzle, and therefore aligns directly from the shot chamber.

If you would like to discuss how Wetron can help you with your aluminum die casting project, please contact us directly at sales@wetronindustrial.com with your inquiries.

What Is Hot Chamber Die Casting?

Hot chamber die-casting is a similar process as cold chamber die-casting. The only difference is that the metal is heated directly inside the casting machine instead of going to a separate furnace. Having this built-in furnace is the defining characteristic of hot chamber die-casting.

This built-in furnace helps heat the metal to a molten state and it uses a hydraulic-powered piston to force the molten metal into the die. Here, the molten will be formed into its final shape in as little as 15-20 seconds. Hot chamber die-casting is ideal for metals with a low melting point, such as tin alloys, zinc alloys, and lead alloys.

In a hot chamber die casting machine, the fixed die half is called a cover die, which is mounted to a stationary platen (large plate to which each die half is mounted) and aligns with the nozzle of the gooseneck. The movable die half is the ejector die and is mounted to a movable platen, which slides along tie bars.

The metal is contained in an open holding pot, which is placed in the furnace and melted to the needed temperature. When the plunger is in the “up” position, the molten metal flows into the shot chamber. As the plunger moves down, it forces the molten metal through a gooseneck and into the die at injection pressures ranging from 1,000 – 5,000 psi.

The machine pushes the moving platen towards the cover die and holds it closed with great pressure until the molten metal is injected. The plunger remains in the “down” position to hold the pressure while the casting “cools off.” After solidification, the plunger is retracted and the cast part is either ejected, manually removed from the machine or pushed off the cover die. This ejection system, which includes an ejector die and ejector pins, allows the casting to be pushed out while releasing the die halves.

Difference Between Cold Chamber Die Casting and Hot Chamber Die Casting

The main difference between cold chamber die-casting and hot-chamber die-casting is how the metal is melted. Mainly differences discussed in below list.

Cold Chamber Die Casting

- Ideal for metals with a high melting point

- Heating chamber located outside of the machine

- For Al, Mg, Cu, and high-melting alloys

- High production but not as fast as hot chamber die-casting

Hot Chamber Die Casting

- Ideal for metals with a low melting point

- Heating chamber included

- For Zn, Ph, and other low-melting alloys

- Fast production but may not be cost-efficient

Which Is Best for Your Operation?

Both hot and cold chamber die casting have pros and cons that you should consider. It’s most important to factor in your project needs to help you determine when it’s appropriate to use which process. Consider the material you’ll need to use, the quantity, your budget, and your timeline to help you decide.

Wetron able to produce custom-fabricated products at an affordable price for your business. Leave message on email for a free quote!