A die casting mold is an essential component in the die casting process. It is responsible for shaping molten alloys into the required complex geometries and dimensional accuracy. The cost of a die casting mold highly depends on various parameters and specifications of the final product. Let us discuss the importance of a high-end die casting mold and the cost factors involved in production.

High-end die casting mold

It plays a vital role in the final quality of die casting product. A well-made die will increase the casting yield, reduce cycle times, and improve dimensional accuracy. It will also enhance the surface finish, minimize porosity, and promote the integrity of die casting product. More, it will improve the overall consistency and repeatability of the die casting process, which is critical for meeting the production targets and maintaining the quality standards.

Here are mainly factors that affect the cost of a die casting mold.

Material Quality

Die casting mold are typically made from different level of steel, which is essential for preventing deformation, resisting wear, resisting high temperatures. The quality of steel used will significantly impact the tool cost.

Complexity

The more complex die casting part is, the more intricate the tooling will be create. The complexity on product will impact the cost of die casting mold.

Size

Bigger size of die casting parts require bigger size of tools compared to smaller one. Tooling build spend much time on preparing and machining.

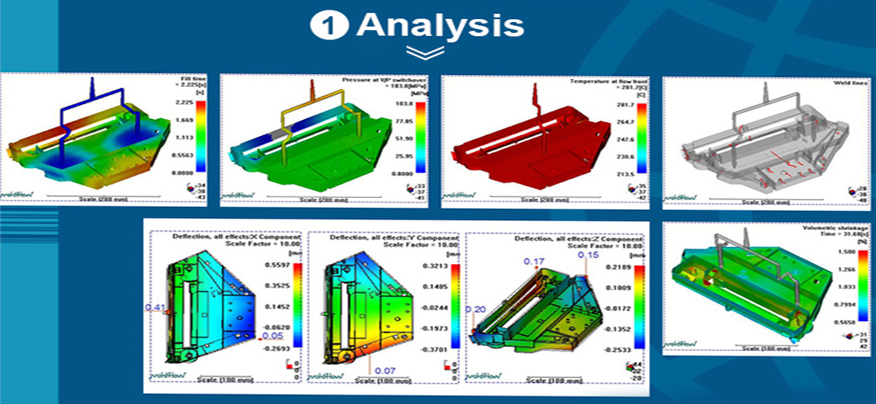

Design

Die casting tool design should ensure the final product is free from surface defects, porosity, and dimensional variations. The design must also be optimized for efficient casting production. The complexity of mold design can significantly impart the tooling cost.

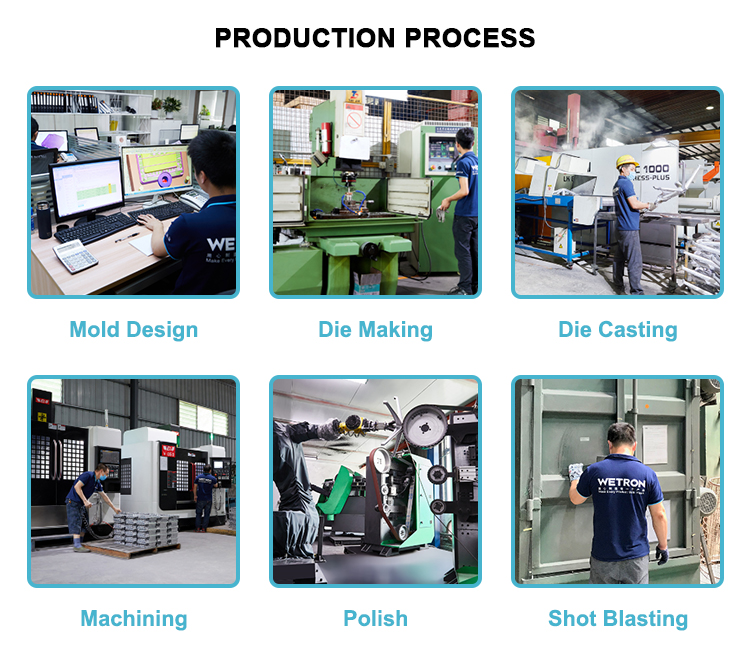

Machining Technology

The cost of die casting mold also depends on machining technology used to develop the tool shape. The tooling industry uses advanced CNC machining centers and precision EDM machines to create the die casting tool.

Expert in Die Cast Tooling Build

With over 15 years of die casting technology, Wetron highly involved the product development with our top-rated customer, more than 200pcs new aluminum parts launched each year. From concept–tooling design–tooling build to manufacturing, we pride ourselves in resolving the most demanding of die casting requirements. Our dedicated team is here to support you at any stage. Contact us directly if you have an idea in mind.