A Brief Overview

High quality chair base are made with aluminum die casting as it is durable and sturdy, also have great support for the body. Perfect appearance is also one of the necessary factors of high quality. We should check its appearance when we complete the first step of the die casting process to see if there are any appearance defects, such as Die Casting shrinkage. Here is the Die Casting shrinkage case for your reference.

| Part Name | Die Casting aluminum chair base | |

| Surface Demand | No cold spot, shrinkage, waterwave, porosity, material missing on surface | |

| Parts Process | Die casting machine | 1000T |

| Plunger Diameter (mm) | 100 | |

| Material | ADC12 | |

| Part weight (g) | 3240 | |

| Part size(mm) | 310*35*575, 5 star chair base | |

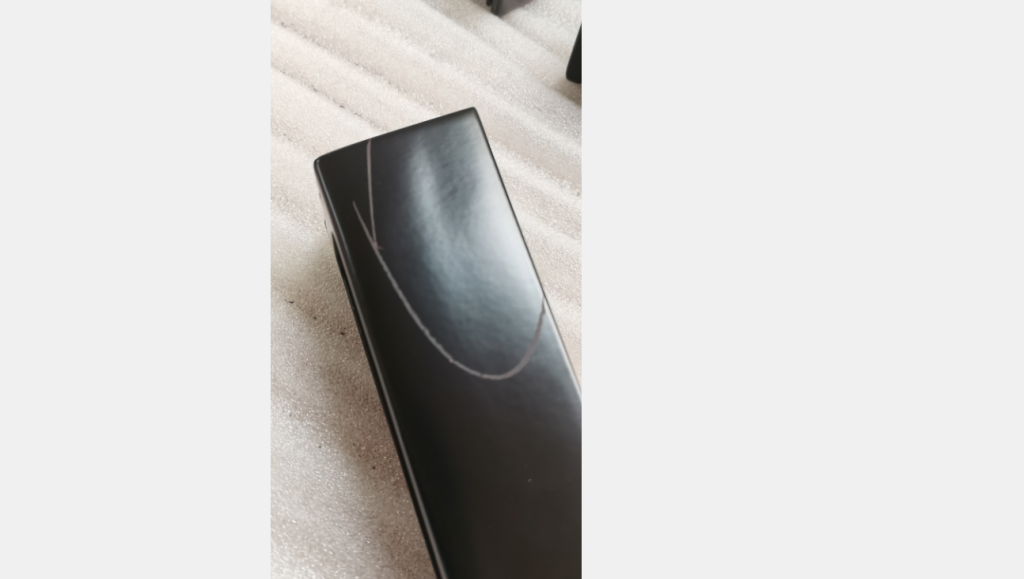

Part Photo

Part Issue

Issue analysis

Aluminum Die Casting Shrinkage is closely related to product structure and temperature.

Solution

1.The structure of the product itself is unlikely to be modified, and it is recommended to adjust by mold temperature. It can be observed that the shrinkage on the opposite side of the gate is not as obvious as near the gate (the product structure is similar), which can reduce the mold temperature near the gate.

2. The Aluminum Die Casting mold temperature is controlled by spraying and cooling water, cooling water is opened when there is no cooling water, and flow rate is adjusted when there is.

3. If the mold is opened, try to open the distance between the product and the shunt cone, which is relatively close.

Have a project in mind?

Wetron aluminum die casting services for lighting

industrial parts are applied in several leading markets. We meet customers

demands for high quality demands ranging from aluminum die casting chair

base and other aluminum furniture components. We take great

pride in our ability to optimize the tooling and manufacturing.

Contact us

Contact us directly and find out more and also see how we can save you time and money on manufactured components.